With a focus on the next industrial revolution driven by the digital transformation of the manufacturing industries with additive manufacturing being the cornerstone of this revolution, the first Additive Manufacturing Conference (AMC) Turkey was held on October 17th to 19th 2019 in Istanbul, Turkey.

The aim of the conference was to create a common platform for sharing scientific research and R&D studies on Additive Manufacturing technologies where the scientific community and researchers from industry come together.

AMC TURKEY brought local and international scientists, researchers, and representatives both from academia and industry, where they presented and shared their recent scientific discoveries, research activities and emerging applications in Additive Manufacturing and related technologies.

The conference was graced by the presence of internationally-renowned speakers such as Jean Pierre Kruth and Eujin Pei, as well as panel discussions and industrial presentations.

One of the objectives of the AMC TURKEY was to act as a bridge between academia and industry in Additive Manufacturing Technologies. The cooperation between academia and industry is expected to further extend the knowledge and the possible applications of additive manufacturing and ultimately benefit both.

The conference was a massive hit and was well appreciated by the audience. The audience was mesmerized by the many keynote speakers where I have chosen talks from two of them, namely Jean Pierre Kruth and Dr. Eujin Pei.

Jean Pierre Kruth

Jean-Pierre Kruth

Belgian engineer Jean-Pierre Kruth has spent much of his career bringing additive manufacturing from its origins in the 1980s to a vital and growing sector of the 21st-century industry. Jean-Pierre Kruth received a doctorate from the Katholieke Universiteit Leuven (KU Leuven) in Belgium in 1979. He is also the winner of the 2015 Bower Science Award for 3D printing research.

He has worked extensively on additive manufacturing technologies and more so on Stereolithography.

Kruth is also the co-founder of three companies including Materialise, Inc. – one of the leading additive manufacturing companies in the world, LayerWise, which specializes in software and tools for other types of 3D printing processes used to produce metal parts, such as selective laser sintering/melting (SLS/SLM) & Nikon Metrology that develops software, techniques, and instruments for all kinds of industrial metrology applications including laser scanning, MRI/CT systems, microscopes, and even portable metrology devices.

Kruth has more than 500 papers, published in leading scientific and engineering journals worldwide that are among the most cited references in the AM field.

Jean Pierre Kruth at AMC Turkey 2019

At the AMC Turkey 2019 conference, Jean Pierre Kruth started his lecture by explaining about the additive and subtractive processes. This was basically to lay a foundation for what was to follow. The focus of the lecture was more towards the use of lasers in manufacturing and how its careful and optimized usage can lead to varying results as needed and desired for different products.

Lasers are quite complex and they can perform multiple functions and at the same time, they are not entirely exhaustive like a regular tool.

Lasers are used in SLM (Selective Laser Melting) but are also equally effective for SLE (Selective Laser Erosion) and SLR (Selective Laser Remelting)

Remelting one time gives 99.96% density, It is beneficial for the ratio between density and cost to remelt only each sixth layer which then reduces post-processing like HIP

Another advantage of remelting is that it enhances the surface quality as tested by experts. However, elevated edges that tend to occur with SLM can be reduced by SLE and also precision for holes can be increased with SLE.

Dr. Eujin Pei

Dr. Eujin Pei (Third from left)

Dr. Eujin Pei is the Programme Director for the BSc Product Design; and Programme Director for the BSc Product Design Engineering courses at Brunel University. He is also the Director for Postgraduate Research, ensuring the quality and standards for all Ph.D. students within the Department.

Dr. Eujin’s research interest centers on Functionally Graded Additive Manufacturing and 4D Printing. He gained hands-on experience as a Research Fellow at Loughborough University, Brunel University London and at the University of Southampton.

Dr. Eujin has multiple Ph.D. research topics for his name. Some of them are as mentioned; Developing a Novel Approach for the Virtual Simulation of 4D Printed, Integration of Mixed Reality and 4D Printing, Building a Knowledge Repository – Shape Memory Materials for Additive Manufacturing, etc.

Dr. Eujin Pei at AMC Turkey 2019

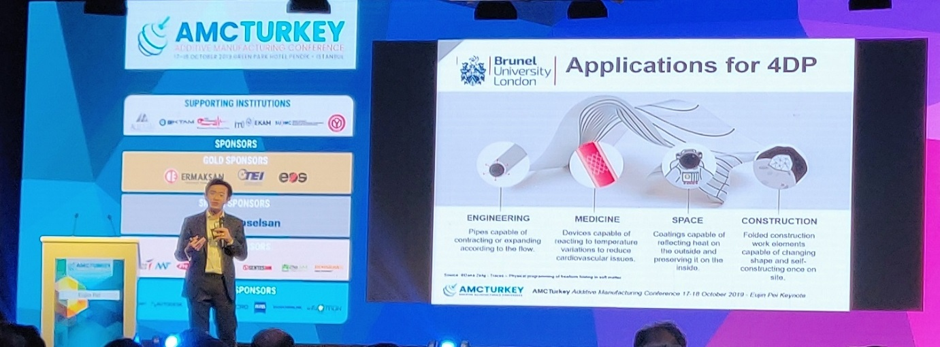

Dr. Eujin Pei delivering a lecture on 4D printing at the AMC Turkey 2019

Dr. Eujin Pei’s lecture was truly interesting in many ways. The core focus of his lecture was on 4D printing and the roadmap ahead for the same. Through the slide, Dr. Eujin put forth that at present 4D printing is still in its nascent stage and researchers are working on the 4D materials and 4D printing processes. Over the next 5-10 years, the research will shift towards 4DP modeling & simulation with design for 4D printing and design guidelines for the same.

Over the next two to three decades, the research will move towards H&S disposal and certification of parts. Beyond this, 4D printing will have widespread applications and will move towards 5D printing which will basically be embedded intelligence.

Apart from stating this roadmap, Dr. Eujin also talked about how multinationals like Autodesk and research institutes like MIT are already involved in developing simulation software for 4D printing.

According to Dr. Eujin, the major applications for 4D printing is and will be in Engineering, Medicine, Space, and Construction.